Dive Brief:

- Heineken is joining forces with Siemens for a long-term decarbonization program intended to minimize energy consumption and reduce 50% of carbon dioxide emissions at over 15 beer and malt production facilities across the U.S., Europe and Asia by 2025.

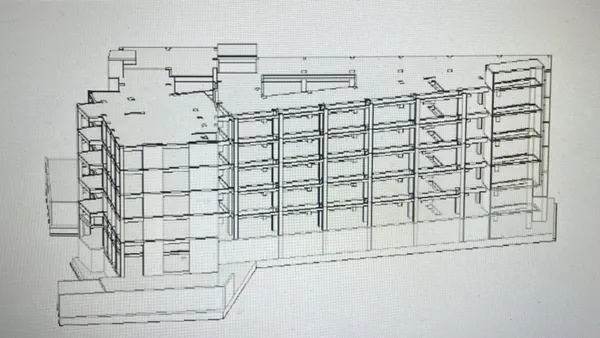

- Using operational data, alongside an energy digital twin at each Heineken site, Siemens will design, engineer and implement a system to electrify heat and cooling production through renewable energy-powered heat pumps, according to a Jan. 16 news release.

- The collaboration follows a previous advisory project that involved deploying an energy twin to simulate and analyze a standard Heineken brewery in a virtual environment, the release said. The simulation showed that the heating and cooling generation necessary for the brewing process accounts for roughly 70% of brewery energy use, with Siemens estimating that optimizing and monitoring these heating and cooling systems can yield potential energy savings of 15% to 20% per site and an average 50% reduction in carbon dioxide emissions.

Dive Insight:

Heineken said the partnership will support its global Net Zero Production roadmap, which aims to achieve net-zero scope 1 and scope 2 emissions by 2030 and net-zero emissions across the full value chain by 2040.

“As we continue to focus on the delivery of our journey to reach net zero in scope 1 and 2, we know that we must make many bold and ambitious moves to decarbonize our global operations,” Heineken CEO and Chairman Dolf van den Brink said in the release. Van den Brink added that partnering with Siemens will provide Heineken the technical expertise needed to implement next-generation solutions to its facilities at scale.

As part of the partnership, Siemens Cooling Plant Optimization algorithms will be used to monitor, control and optimize the new system to electrify the production of heat and cooling, the release said. These algorithms utilize built-in analytics to analyze data from the plant, reduce energy costs and ensure operational efficiency, it said. As part of the agreement, Siemens will also deliver a five-year performance and monitoring contract, connecting the breweries to its systems that draw on data services to monitor the production sites remotely, per the release.

“By collaborating on an end-to-end program, we’re able to combine hardware, software and analytics to predict and deliver the long-term results which are now crucial to every industry,” Matthias Rebellius, managing board member of Siemens AG and CEO of Smart Infrastructure, said in the release.

While traditional building decarbonization measures have involved costly and onerous physical energy audits, drawing on AI and machine learning algorithms for endeavors like heating and cooling system assessments can help determine pathways for reaching net-zero emissions more quickly, with financially optimized plans that can be generated for an entire portfolio within weeks, according to a report from McKinsey.

Heineken said it continues to focus on “concrete actions to reduce its carbon emissions” by working closely with customers, consumers and suppliers. From 2018 through the end of 2022, the company has cut 18% of total scope 1 and scope 2 emissions by boosting its renewable energy consumption to 58%, according to the release. The company says that additional sites will be added to the second phase of its project with Siemens as it continues to invest in renewable heat solutions for its breweries.