Dive Brief:

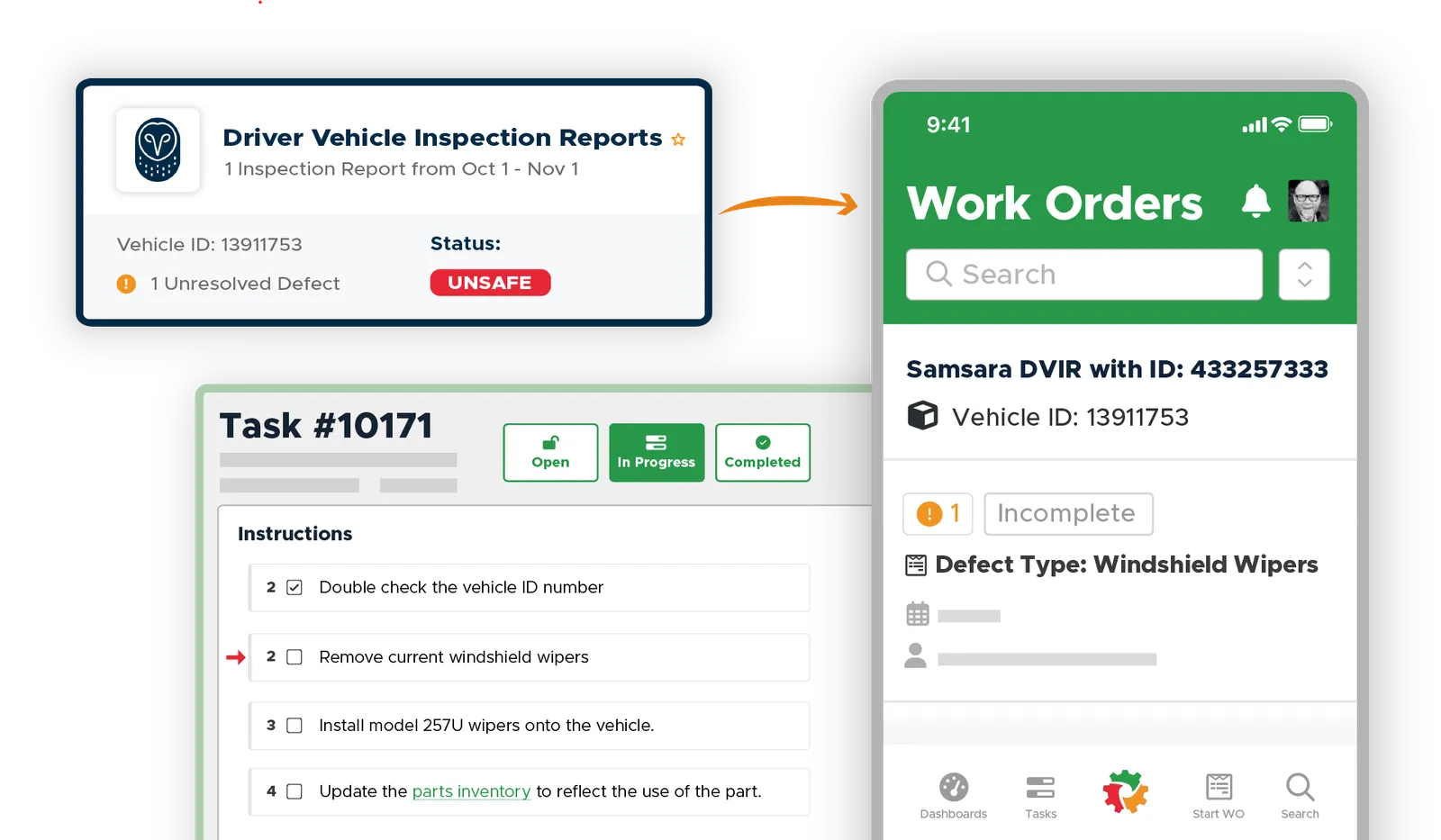

- Limble has created a closed-loop integration with Samsara to help facilities managers who oversee vehicle fleets connect data from internet-of-things sensors to their computerized maintenance management systems.

- Limble’s CMMS will leverage data from Samsara’s connected IoT device cloud to automate maintenance workflows by incorporating diagnostics, driver vehicle inspection reports and utilization data, Limble said.

- By automating the creation of preventive maintenance tasks, streamlining work orders for inspection defects and ensuring consistent vehicle asset information, the integration will result in “fewer equipment failures, better reporting and easier maintenance management,” Limble’s CEO and founder, Bryan Christiansen, said in an interview.

Dive Insight:

Limble’s CMMS software is designed to help maintenance professionals implement maintenance programs, manage assets, streamline workflows, organize work orders and control their inventory. Samsara’s connected operations platform seeks to enable organizations tracking fleets and other equipment to enhance operational efficiencies. The integration creates a single closed-loop system for the fleet maintenance workflow needs of customers across the construction, transportation, warehousing, logistics and manufacturing sectors, Limble said in a Nov. 14 release.

“Facilities managers using siloed systems can run into data discrepancies and unnecessary manual workflows,” Christiansen told Facilities Dive. The integration provides real-time sensor data that automatically triggers preventive maintenance tasks, removing the need for manual sensor checks to determine maintenance requirements.

“As a result, facilities managers can reduce excessive maintenance, equipment downtime and the associated costs,” Christiansen said.

New work orders are generated automatically in Limble when a defect is reported in Samsara. As soon as the work order is completed and closed out in Limble, that defect is resolved in Samsara, removing the need to update multiple systems, Limble said.

Against the backdrop of aging equipment, higher labor costs involving service technicians and a supply chain squeeze, predictive maintenance remains an ongoing challenge for companies operating vehicle fleets. A survey of repair shops conducted by the American Trucking Association last year found that 82% of fleets faced supply chain disruptions last year due to parts shortages, with 14% categorizing these disruptions as severe, Freight Waves reported.

“Supply chain disruptions and chip shortages have further exacerbated the stress on fleets to ensure their trucks and equipment are in working order, yet few are empowering their maintenance teams with the proper technology to mitigate the impact of these issues,” Limble’s product incubation head, Scott Knudson, said in the release.

“Marrying real-time vehicle sensor data such as odometer miles and engine hours with robust maintenance management functionality” increases overall efficiency and prevents equipment failures before they occur, Christiansen said.

Earlier this year, Limble raised $58 million from Goldman Sachs. At that time, the CMMS provider said it would channel that series B funding toward expanding its user interface and product portfolio.