Dive Brief:

- MachineQ has launched an Internet of Things-based power monitoring system to help enterprises manage costs and support their sustainability efforts, the company said in a a Sept. 3 news release.

- The solution offers various ways to track and manage their energy consumption through IoT sensor devices that can extract data at the receptacle, equipment or breaker level. This can aid operators in predictive maintenance for critical equipment by detecting anomalies in power consumption, which often indicate equipment issues, MachineQ said.

- The system is particularly relevant for high-energy consumers such as food service companies, laboratories and hotels that consume more energy than typical commercial buildings due to their energy-intensive equipment and asset-intensive operations, MachineQ said.

Dive Insight:

Restaurants use about five to seven times more energy per square foot than other commercial buildings, with high-volume quick-service restaurants likely to use as much as 10 times more energy per square foot than other commercial facilities, according to Energy Star, a program managed by the U.S. Environmental Protection Agency.

Laboratories consume five to 10 times more energy per square foot than office buildings on average, according to the EPA. The agency notes that in some specialized laboratories such as clean rooms and labs with larger process loads, this number can rise to as much as 100 times the energy used in a similarly sized institutional or commercial structure. Pharmaceutical firms’ asset-heavy and power-intensive lab operations could especially benefit from asset-level power monitoring, MachineQ said.

By tracking energy consumption of equipment, such as ultra-low temperature freezers and centrifuges, operators can correlate data on consumption with how frequently or infrequently assets are used, identifying opportunities to reduce energy use and determining whether to move assets to other locations, as needed, Machine Q said. The monitoring system will also help lab managers decommission appliances, make more informed purchasing decisions, detect anomalies in power consumption — often an indicator of equipment issues — and proactively service or replace units before they fail, per the release.

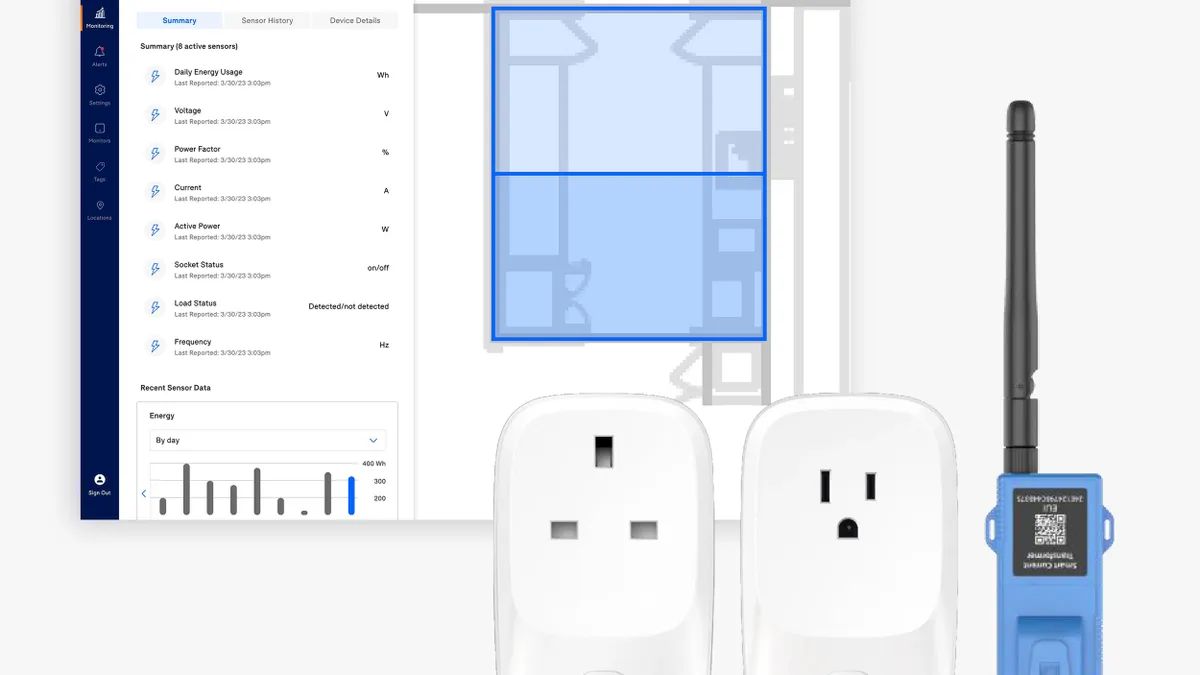

The system collects data through the MQpowerCT, a wireless, self-powered current transformer that can be clamped to electrical conductors at the breaker or asset level to measure real-time current consumption, and MQpower SP, a smart plug load device that enables business to plug in equipment and assets to extrapolate energy data, MachineQ said.

The MQpowerSP device, which can provide daily energy use, instantaneous current, voltage, active power and power factor readings, supports various plug types including U.S., UK and EU types.

The MQpowerCT and MQpowerSP solutions both support regional low-power, wide-area networking, or LoRaWAN, frequencies globally, according to the release.

MachineQ, which is owned by Comcast, said the technology is built on its existing network infrastructure, helping customers to lower the total cost of ownership of their IoT investments over time.

“We’ve seen increased demand from current and prospective customers seeking ways to understand power consumption and obtain executable data to help them reduce energy utilization,” Bryan Witkowski, head of product and strategy at MachineQ, said in the release. “This solution offers customers flexible options to help not only monitor but also help manage their energy usage. Plus, with many companies focused on sustainability initiatives, this solution can help play a vital role towards measuring and achieving those efforts.”

The solution comes as operators and technology providers tackle the large amount of energy used by equipment plugged into outlets, which may account for up to 25% of total energy consumption in minimally code-compliant office buildings, according to the U.S. Government Services Administration.